Creating Decision Trees for Classification Problems – Machine Failure Prediction

Problem Statement

Business Context

System failure is a common issue across the manufacturing industry, where a variety of machines and equipment are used. In most cases, it becomes important to be able to predict machine failures by analyzing system data and taking preventive measures to be able to tackle them. This is known as predictive maintenance and with the rising availability of data and computational resources, the use of such data-driven, proactive maintenance methods has resulted in several benefits like minimized downtime of the equipment, minimized cost associated with spares and supplies, etc.

AutoMobi Engineering Pvt. Ltd is an auto component manufacturing company. The manufacturing facility of AutoMobi consists of numerous products machined on several CNC (Computer Numerical Controlled) machines. In an attempt to transition to a data-driven maintenance process, the company had set up sensors in various locations to collect data regarding the various parameters involved in the manufacturing process. Initially, they want to try it in an injector nozzle manufacturing shop where they are manufacturing fuel injector nozzles for automobile engines using various manufacturing processes (like turning, drilling, etc). The company has been collecting data on an hourly basis from these sensors and aims to build ML-based solutions using the data to optimize cost, improve failure predictability, and minimize the downtime of equipment.

Objective

AutoMobi has recently been encountering a problem with frequent equipment failure in the fuel injector nozzle manufacture unit, leading to disturbance in the manufacturing process. They have reached out to the Data Science team for a solution and shared data for the past three months. As a member of the Data Science team, you are tasked with analyzing the data and developing a Machine Learning model to detect potential machine failures, determine the most influencing factors on machine health, and provide recommendations for cost optimization to the management.

Dataset

Data Description

The data contains the different attributes of machines and health. The detailed data dictionary is given below.

Data Dictionary

- UDI: Unique identifier ranging from 1 to 10000

- Type: The type of product consisting of low(60% of all products), medium(30%), and high(10%) quality corresponding to L, M, and H

- Air temperature: Ambient temperature (in the machine shop) measured in Kelvin

- Process Temperature: Tool tip temperature measured in Kelvin

- Rotational Speed: Rotational speed of the machine spindle measured in revolutions per minute (rpm)

- Torque: Torque acting on the machine spindle measured in Newton meter (Nm)

- Tool wear: Tool wear measured in micrometers (During the manufacturing process, continuous rubbing of the tool on the workpiece leads to the wearing of the tool material. The tool wear is measured as the amount of wear on the cutting face of the tool measured in micrometers)

- Failure: 0-No failure, 1-Failure

Importing the necessary libraries

In [ ]:

# this will help in making the Python code more structured automatically (help adhere to good coding practices)

%load_ext nb_black

import warnings

warnings.filterwarnings("ignore")

# Libraries to help with reading and manipulating data

import pandas as pd

import numpy as np

# libaries to help with data visualization

import matplotlib.pyplot as plt

import seaborn as sns

# Removes the limit for the number of displayed columns

pd.set_option("display.max_columns", None)

# Sets the limit for the number of displayed rows

pd.set_option("display.max_rows", 200)

# setting the precision of floating numbers to 5 decimal points

pd.set_option("display.float_format", lambda x: "%.5f" % x)

# Library to split data

from sklearn.model_selection import train_test_split

# To build model for prediction

from sklearn.tree import DecisionTreeClassifier

from sklearn import tree

# To tune different models

from sklearn.model_selection import GridSearchCV

# To get diferent metric scores

from sklearn.metrics import (

f1_score,

accuracy_score,

recall_score,

precision_score,

confusion_matrix,

make_scorer,

)

Loading the dataset

In [ ]:

df_main = pd.read_csv("Predictive_Maintenance_Case_Study.csv")

In [ ]:

# copying data to another variable to avoid any changes to original data data = df_main.copy()

Overview of the dataset

View the first and last 5 rows of the dataset.

In [ ]:

data.head()

Out[ ]:

| UDI | Type | Air temperature | Process temperature | Rotational speed | Torque | Tool wear | Failure | |

|---|---|---|---|---|---|---|---|---|

| 0 | 1 | M | 298.10000 | 323.74074 | 1551 | 42.80000 | 0 | 0 |

| 1 | 2 | L | 298.20000 | 324.11111 | 1408 | 46.30000 | 3 | 0 |

| 2 | 3 | L | 298.10000 | 323.37037 | 1498 | 49.40000 | 5 | 0 |

| 3 | 4 | L | 298.20000 | 323.74074 | 1433 | 39.50000 | 7 | 0 |

| 4 | 5 | L | 298.20000 | 324.11111 | 1408 | 40.00000 | 9 | 0 |

In [ ]:

data.tail()

Out[ ]:

| UDI | Type | Air temperature | Process temperature | Rotational speed | Torque | Tool wear | Failure | |

|---|---|---|---|---|---|---|---|---|

| 9995 | 9996 | M | 298.80000 | 323.00000 | 1604 | 29.50000 | 14 | 0 |

| 9996 | 9997 | H | 298.90000 | 323.00000 | 1632 | 31.80000 | 17 | 0 |

| 9997 | 9998 | M | 299.00000 | 323.74074 | 1645 | 33.40000 | 22 | 0 |

| 9998 | 9999 | H | 299.00000 | 324.11111 | 1408 | 48.50000 | 25 | 0 |

| 9999 | 10000 | M | 299.00000 | 324.11111 | 1500 | 40.20000 | 30 | 0 |

- There are three types of products those are L, M, and H (Low, Medium, and High quality).

- The

UDIcolumn is containing unique values.

Understand the shape of the dataset.

In [ ]:

data.shape

Out[ ]:

(10000, 8)

- The dataset has 10000 rows and 8 columns.

Check the data types of the columns for the dataset.

In [ ]:

data.info()

<class 'pandas.core.frame.DataFrame'> RangeIndex: 10000 entries, 0 to 9999 Data columns (total 8 columns): # Column Non-Null Count Dtype --- ------ -------------- ----- 0 UDI 10000 non-null int64 1 Type 10000 non-null object 2 Air temperature 10000 non-null float64 3 Process temperature 10000 non-null float64 4 Rotational speed 10000 non-null int64 5 Torque 10000 non-null float64 6 Tool wear 10000 non-null int64 7 Failure 10000 non-null int64 dtypes: float64(3), int64(4), object(1) memory usage: 625.1+ KB

- The

Typecolumn is of object type while the rest columns are numeric in nature

Checking for missing values

In [ ]:

# checking for null values data.isnull().sum()

Out[ ]:

UDI 0 Type 0 Air temperature 0 Process temperature 0 Rotational speed 0 Torque 0 Tool wear 0 Failure 0 dtype: int64

- There are no null values in the dataset

Dropping the duplicate values

In [ ]:

# checking for duplicate values data.duplicated().sum()

Out[ ]:

0

- There are no duplicate values in the data.

Dropping the columns with all unique values

In [ ]:

data.UDI.nunique()

Out[ ]:

10000

- The

UDIcolumn contains only unique values, so we can drop it

In [ ]:

data = data.drop(["UDI"], axis=1)

Statistical summary of the data

Let’s check the statistical summary of the data.

In [ ]:

data.describe().T

Out[ ]:

| count | mean | std | min | 25% | 50% | 75% | max | |

|---|---|---|---|---|---|---|---|---|

| Air temperature | 10000.00000 | 300.00493 | 2.00026 | 295.30000 | 298.30000 | 300.10000 | 301.50000 | 304.50000 |

| Process temperature | 10000.00000 | 328.94652 | 5.49531 | 313.00000 | 324.48148 | 329.29630 | 333.00000 | 343.00000 |

| Rotational speed | 10000.00000 | 1538.77610 | 179.28410 | 1168.00000 | 1423.00000 | 1503.00000 | 1612.00000 | 2886.00000 |

| Torque | 10000.00000 | 39.98691 | 9.96893 | 3.80000 | 33.20000 | 40.10000 | 46.80000 | 76.60000 |

| Tool wear | 10000.00000 | 107.95100 | 63.65415 | 0.00000 | 53.00000 | 108.00000 | 162.00000 | 253.00000 |

| Failure | 10000.00000 | 0.03390 | 0.18098 | 0.00000 | 0.00000 | 0.00000 | 0.00000 | 1.00000 |

- The

air temperatureranges from 300K to 304.5K. Usually, machine shops are maintained in control environment so the temperature range looks usual. - The

process temperatureis a bit higher than theair temperatureand that’s quite usual because heat is continuously generated during the machining process. - The

rotational speedhas a max value of 2886rpm while 1612rpm at the 75th percentile. Some of the processes are performed at a higher speed than usual.

Exploratory Data Analysis (EDA) Summary

Note: The EDA section has been covered multiple times in the previous case studies. In this case study, we will mainly focus on the model building aspects. We will only be looking at the key observations from EDA. The detailed EDA can be found in the appendix section.

The below functions need to be defined to carry out the EDA.

In [ ]:

def histogram_boxplot(data, feature, figsize=(15, 10), kde=False, bins=None):

"""

Boxplot and histogram combined

data: dataframe

feature: dataframe column

figsize: size of figure (default (15,10))

kde: whether to show the density curve (default False)

bins: number of bins for histogram (default None)

"""

f2, (ax_box2, ax_hist2) = plt.subplots(

nrows=2, # Number of rows of the subplot grid= 2

sharex=True, # x-axis will be shared among all subplots

gridspec_kw={"height_ratios": (0.25, 0.75)},

figsize=figsize,

) # creating the 2 subplots

sns.boxplot(

data=data, x=feature, ax=ax_box2, showmeans=True, color="violet"

) # boxplot will be created and a triangle will indicate the mean value of the column

sns.histplot(

data=data, x=feature, kde=kde, ax=ax_hist2, bins=bins

) if bins else sns.histplot(

data=data, x=feature, kde=kde, ax=ax_hist2

) # For histogram

ax_hist2.axvline(

data[feature].mean(), color="green", linestyle="--"

) # Add mean to the histogram

ax_hist2.axvline(

data[feature].median(), color="black", linestyle="-"

) # Add median to the histogram

In [ ]:

# function to create labeled barplots

def labeled_barplot(data, feature, perc=False, n=None):

"""

Barplot with percentage at the top

data: dataframe

feature: dataframe column

perc: whether to display percentages instead of count (default is False)

n: displays the top n category levels (default is None, i.e., display all levels)

"""

total = len(data[feature]) # length of the column

count = data[feature].nunique()

if n is None:

plt.figure(figsize=(count + 2, 6))

else:

plt.figure(figsize=(n + 2, 6))

plt.xticks(rotation=90, fontsize=15)

ax = sns.countplot(

data=data,

x=feature,

palette="Paired",

order=data[feature].value_counts().index[:n],

)

for p in ax.patches:

if perc == True:

label = "{:.1f}%".format(

100 * p.get_height() / total

) # percentage of each class of the category

else:

label = p.get_height() # count of each level of the category

x = p.get_x() + p.get_width() / 2 # width of the plot

y = p.get_height() # height of the plot

ax.annotate(

label,

(x, y),

ha="center",

va="center",

size=12,

xytext=(0, 5),

textcoords="offset points",

) # annotate the percentage

plt.show() # show the plot

In [ ]:

def stacked_barplot(data, predictor, target):

"""

Print the category counts and plot a stacked bar chart

data: dataframe

predictor: independent variable

target: target variable

"""

count = data[predictor].nunique()

sorter = data[target].value_counts().index[-1]

tab1 = pd.crosstab(data[predictor], data[target], margins=True).sort_values(

by=sorter, ascending=False

)

print(tab1)

print("-" * 120)

tab = pd.crosstab(data[predictor], data[target], normalize="index").sort_values(

by=sorter, ascending=False

)

tab.plot(kind="bar", stacked=True, figsize=(count + 5, 5))

plt.legend(

loc="lower left", frameon=False,

)

plt.legend(loc="upper left", bbox_to_anchor=(1, 1))

plt.show()

In [ ]:

### function to plot distributions wrt target

def distribution_plot_wrt_target(data, predictor, target):

fig, axs = plt.subplots(2, 2, figsize=(12, 10))

target_uniq = data[target].unique()

axs[0, 0].set_title("Distribution of target for target=" + str(target_uniq[0]))

sns.histplot(

data=data[data[target] == target_uniq[0]],

x=predictor,

kde=True,

ax=axs[0, 0],

color="teal",

stat="density",

)

axs[0, 1].set_title("Distribution of target for target=" + str(target_uniq[1]))

sns.histplot(

data=data[data[target] == target_uniq[1]],

x=predictor,

kde=True,

ax=axs[0, 1],

color="orange",

stat="density",

)

axs[1, 0].set_title("Boxplot w.r.t target")

sns.boxplot(data=data, x=target, y=predictor, ax=axs[1, 0], palette="gist_rainbow")

axs[1, 1].set_title("Boxplot (without outliers) w.r.t target")

sns.boxplot(

data=data,

x=target,

y=predictor,

ax=axs[1, 1],

showfliers=False,

palette="gist_rainbow",

)

plt.tight_layout()

plt.show()

Univariate Analysis

In [ ]:

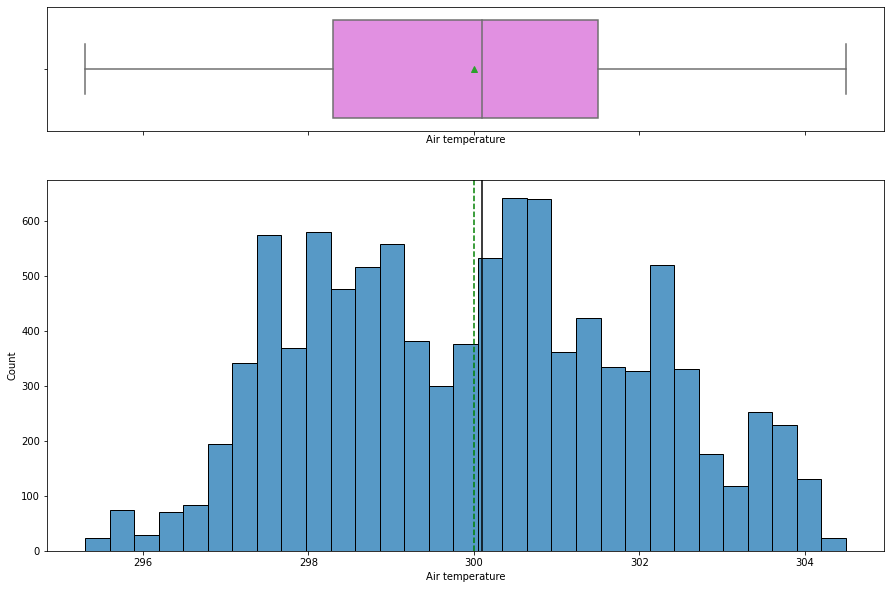

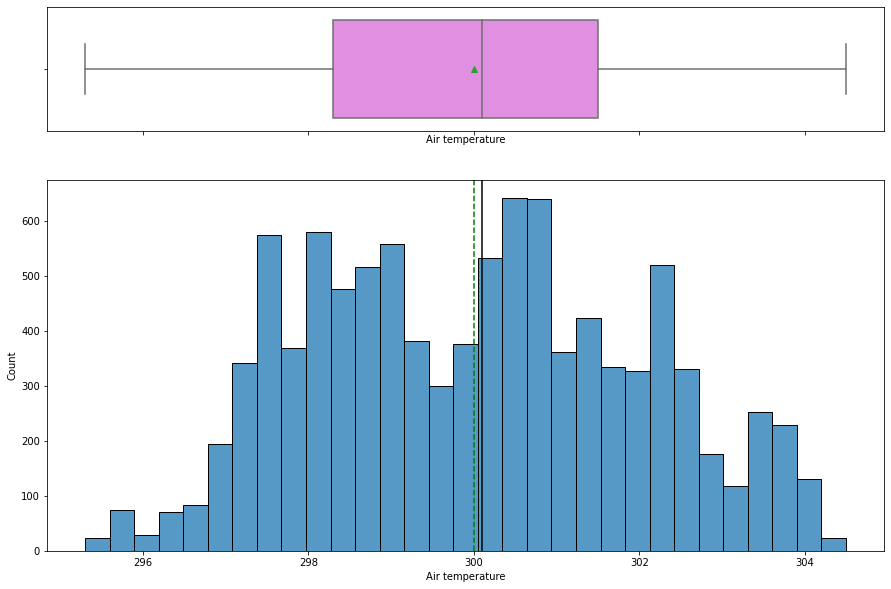

histogram_boxplot(data, "Air temperature")

- The

air temperaturedistribution looks slightly left skewed with a mean temperature around 300K. - There is no outlier present.

In [ ]:

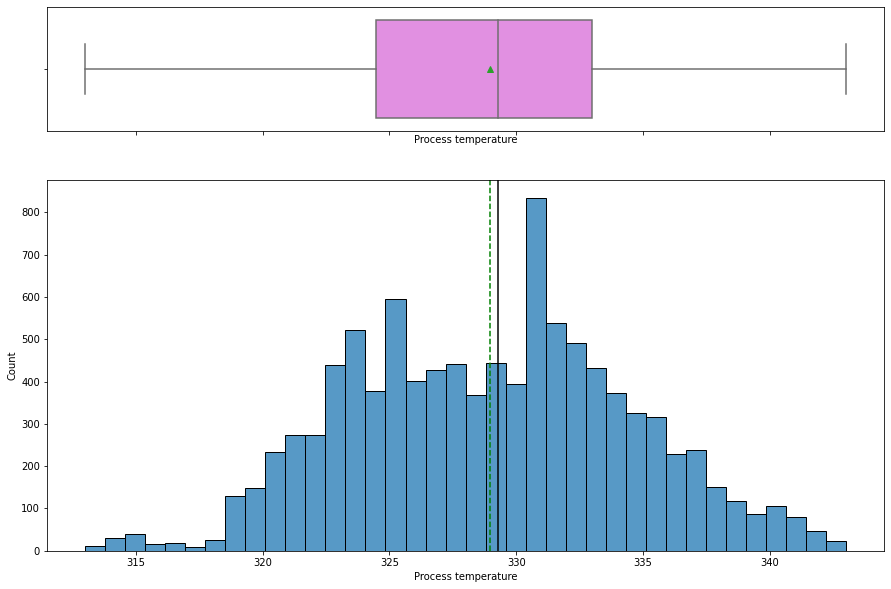

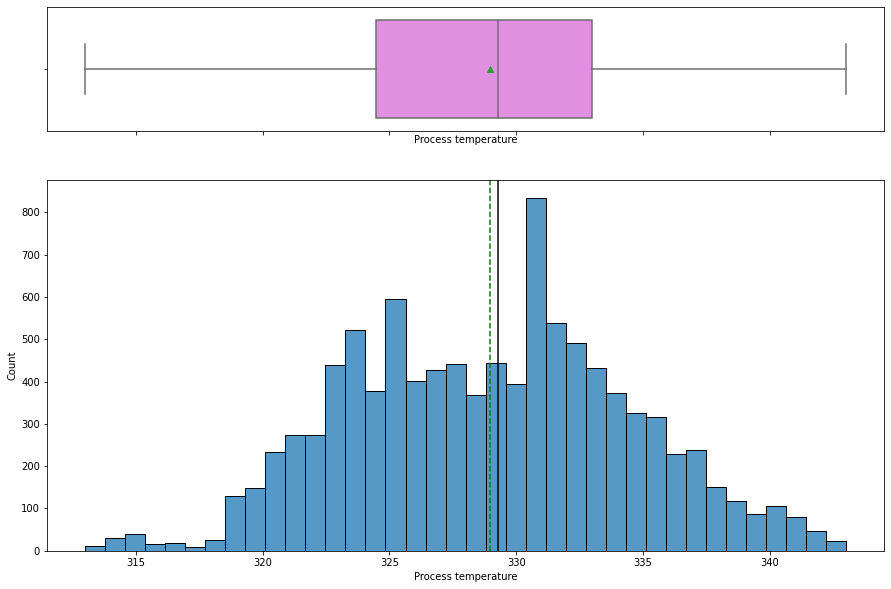

histogram_boxplot(data, "Process temperature")

- The

process temperaturedistribution looks slightly left skewed with a mean temperature around 329K. - There is no outlier present.

In [ ]:

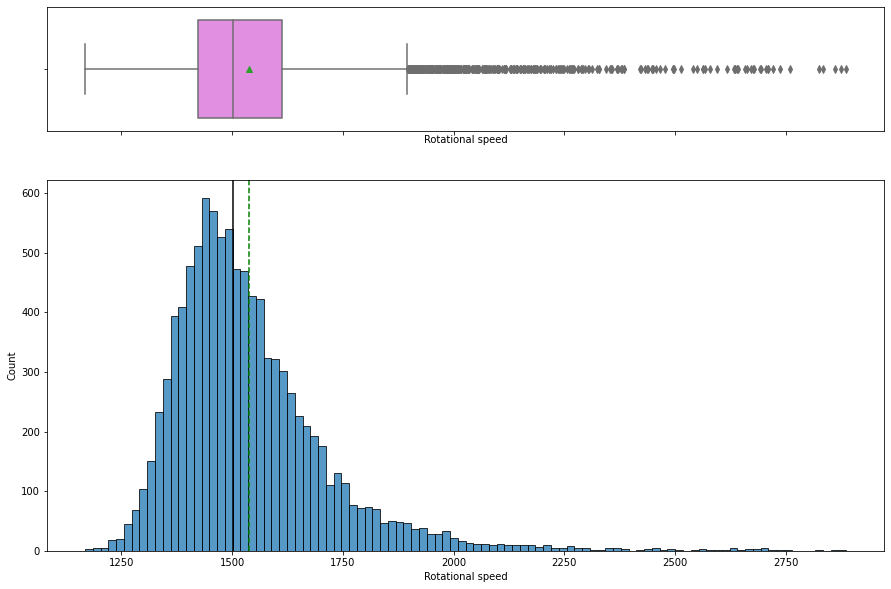

histogram_boxplot(data, "Rotational speed")

- The

rotational speedis right skewed with many outliers on the upper quartile. - Some of the manufacturing operations are performed at a higher speed.

In [ ]:

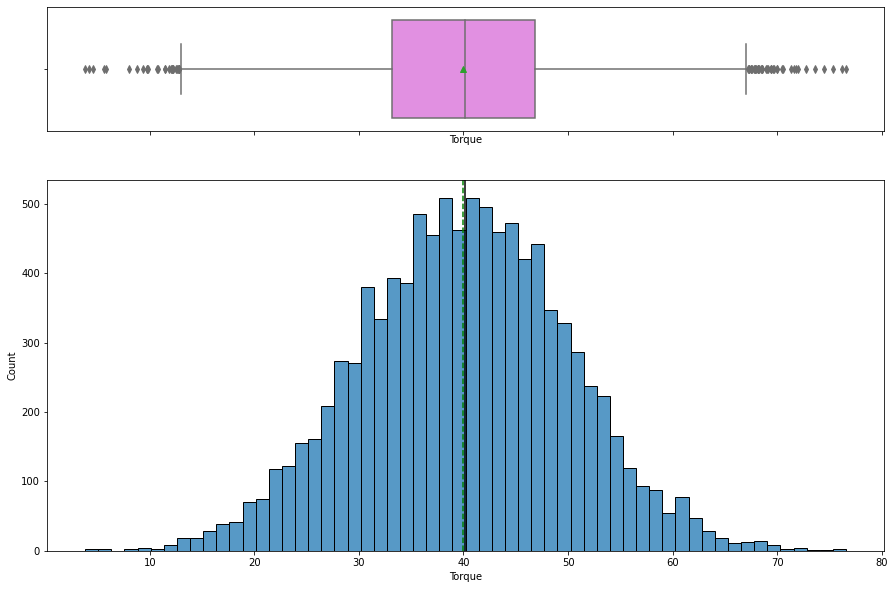

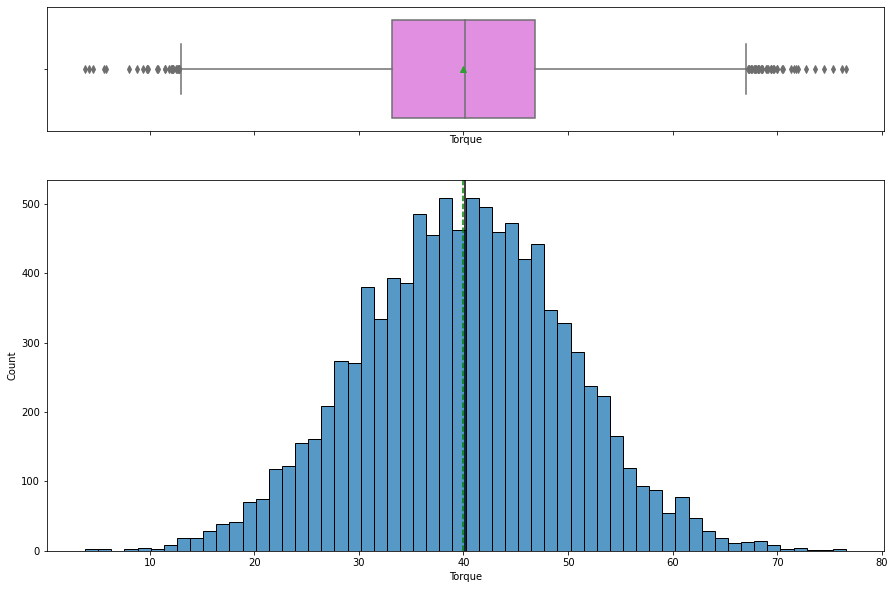

histogram_boxplot(data, "Torque")

- The distribution of

torqueis normal with mean torque around 40 Nm. - Outliers are present on both sides.

In [ ]:

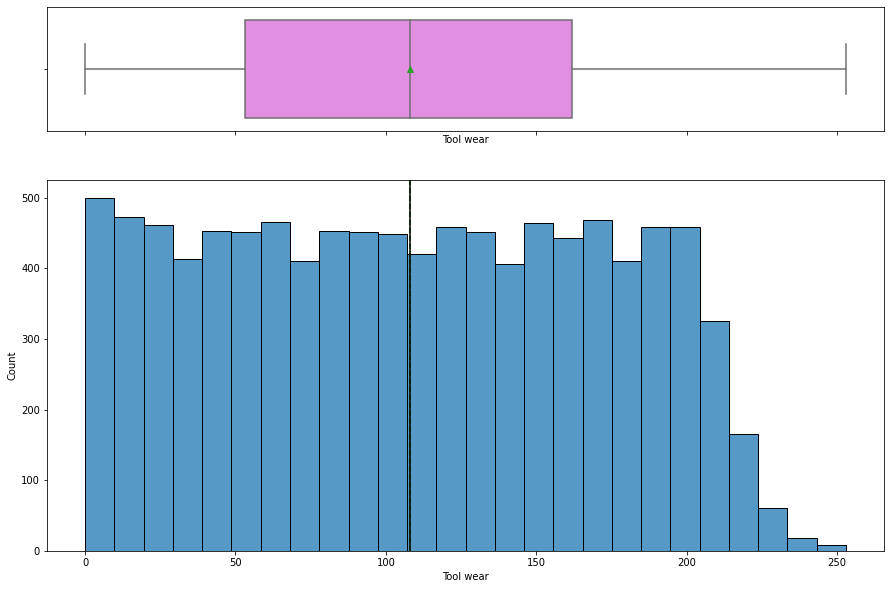

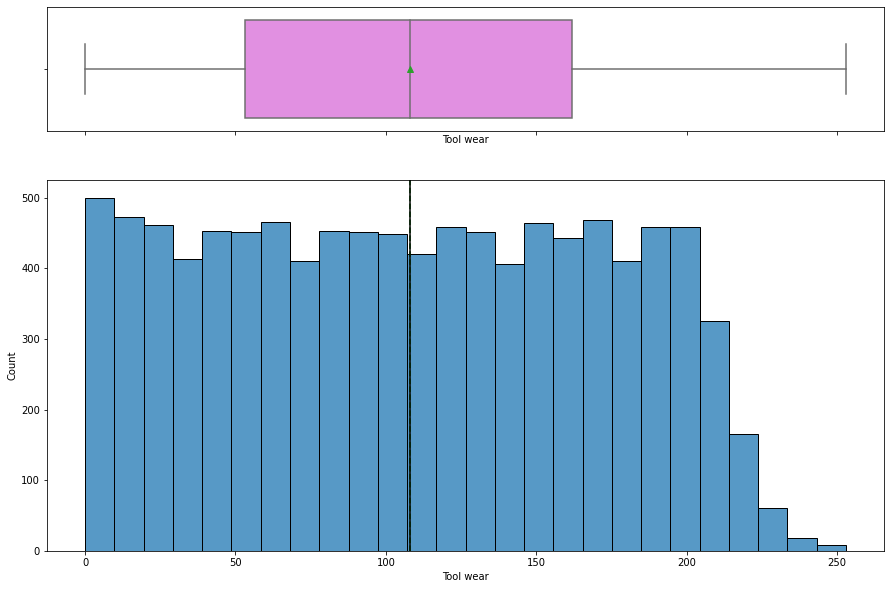

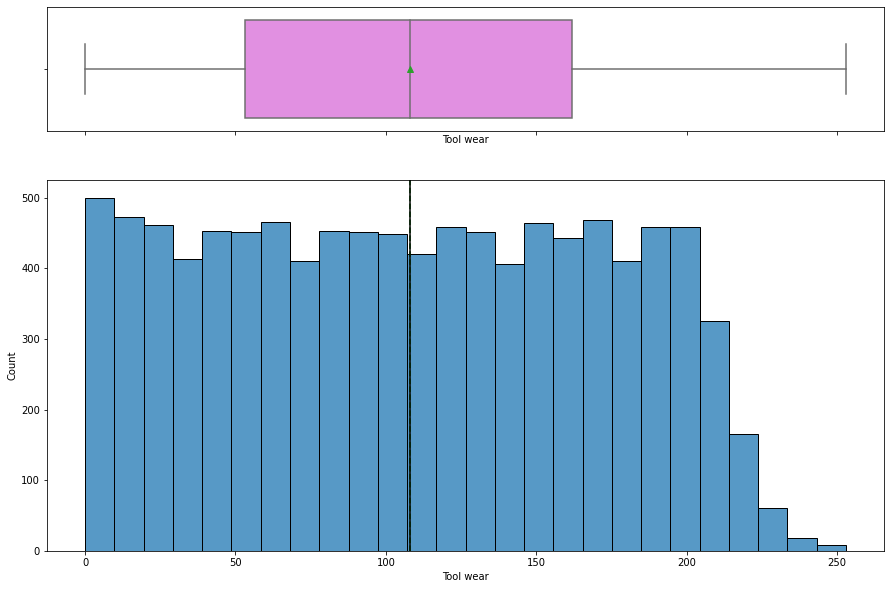

histogram_boxplot(data, "Tool wear")

Tool wearis uniformly distributed with some of the higher values being less frequent.

In [ ]:

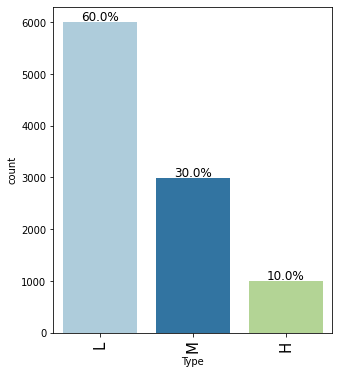

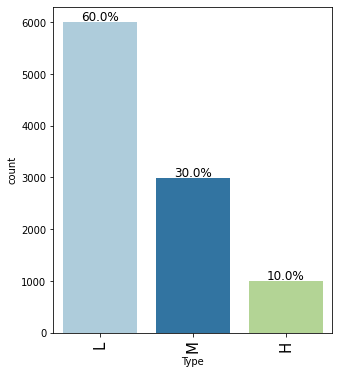

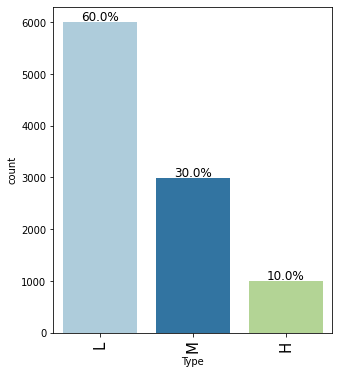

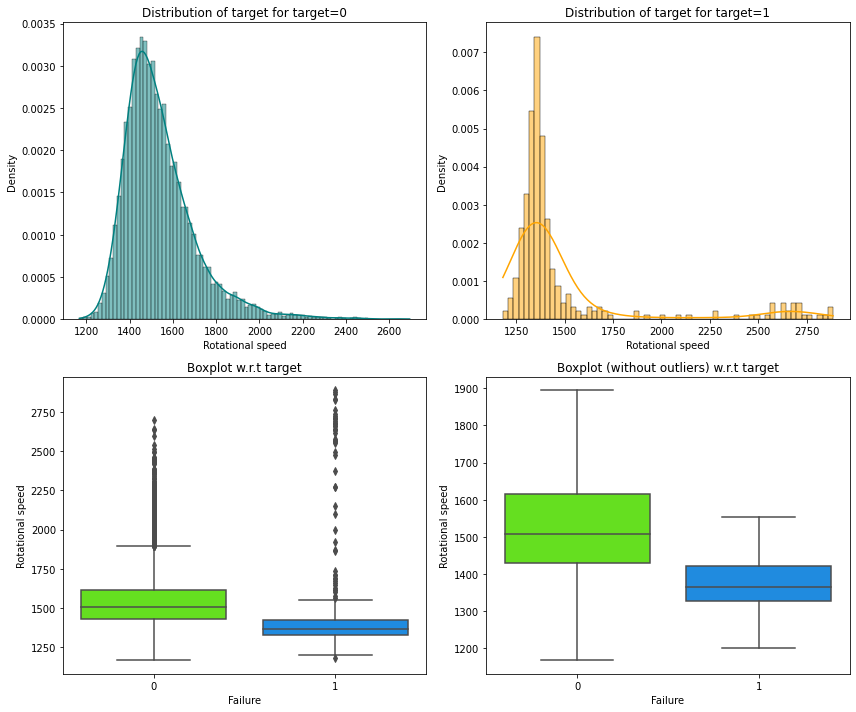

labeled_barplot(data, "Type", perc=True)

- Around 60% of products are of low quality, 30% are of medium quality whereas 10% are of high quality

In [ ]:

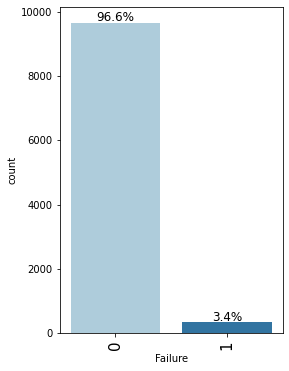

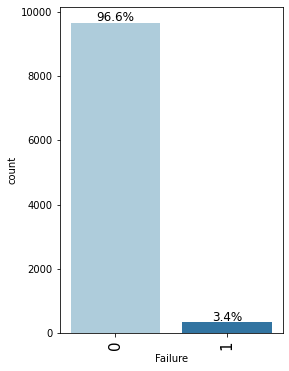

labeled_barplot(data, "Failure", perc=True)

- In 96.6% of observations the machine does not fail while in 3.4% of observations it fails.

Bivariate Analysis

In [ ]:

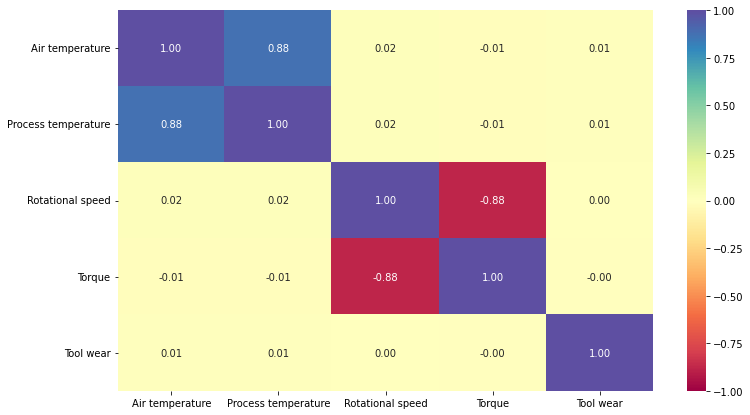

cols_list = data.select_dtypes(include=np.number).columns.tolist()

cols_list.remove('Failure')

plt.figure(figsize=(12, 7))

sns.heatmap(

data[cols_list].corr(), annot=True, vmin=-1, vmax=1, fmt=".2f", cmap="Spectral"

)

plt.show()

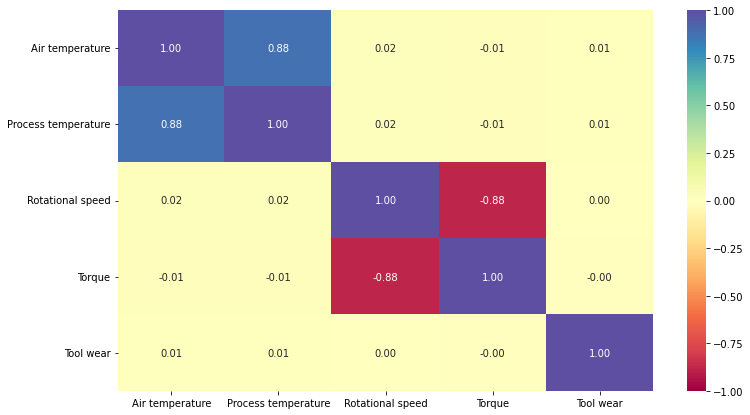

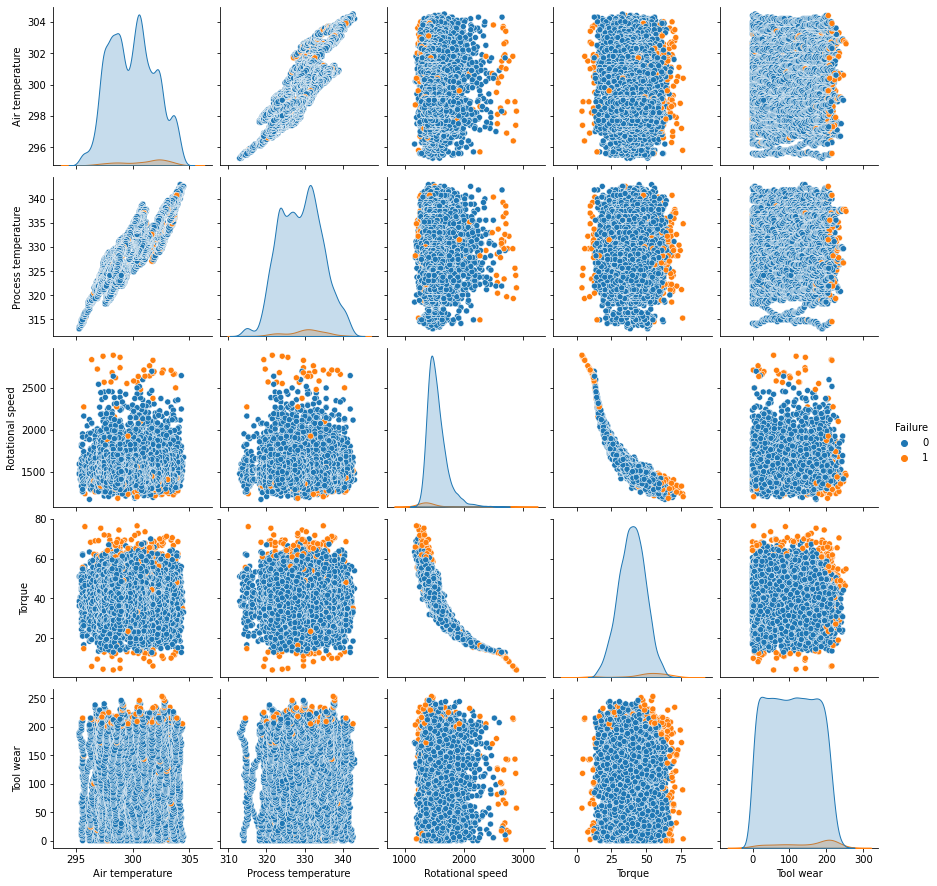

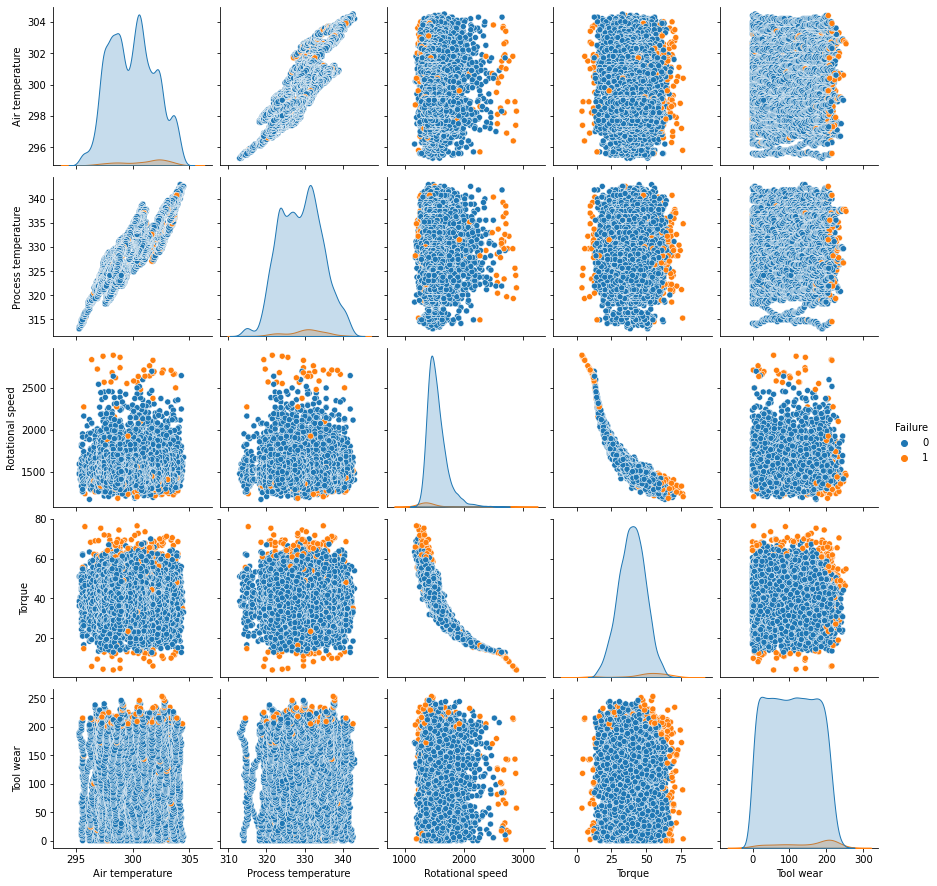

- There’s a positive correlation between the

air temperatureandprocess temperature. - There’s a negative correlation between the

rotational speedandtorque. - No other variables are correlated. We will analyze it further.

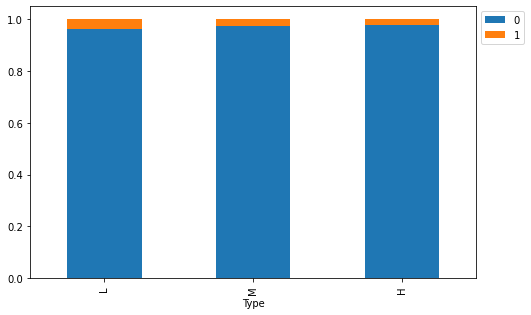

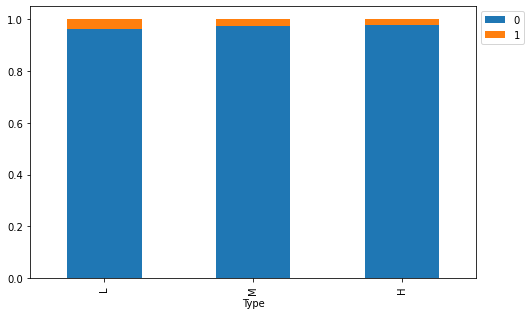

Let’s see how the target variable varies across the type of the product

In [ ]:

stacked_barplot(data, "Type", "Failure")

Failure 0 1 All Type All 9661 339 10000 L 5765 235 6000 M 2914 83 2997 H 982 21 1003 ------------------------------------------------------------------------------------------------------------------------

- Around 70 % of the failure occurred during machining of L type i.e., low-quality products.

- Machining of high-quality products is less prone to failure.

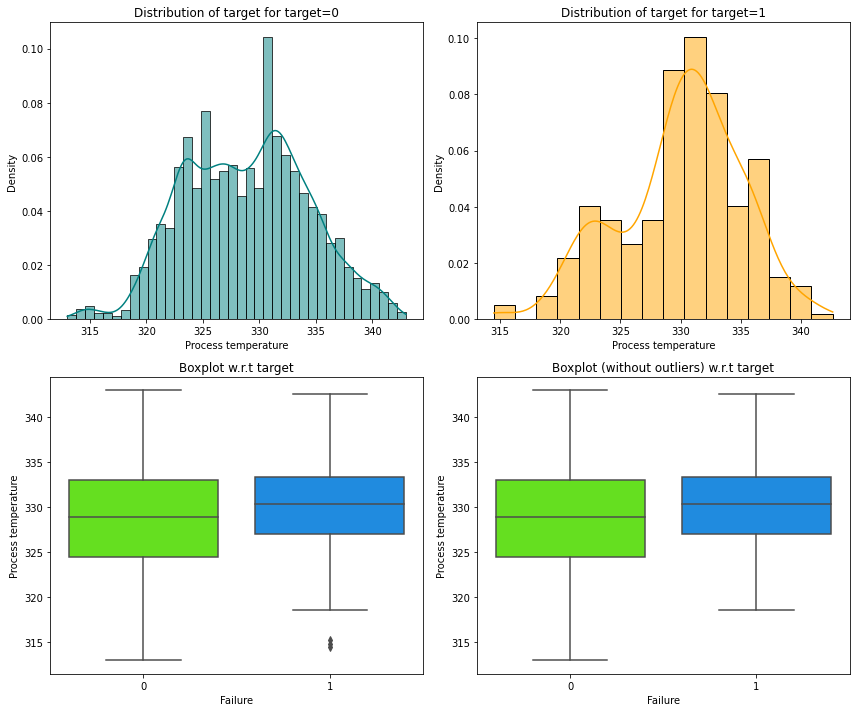

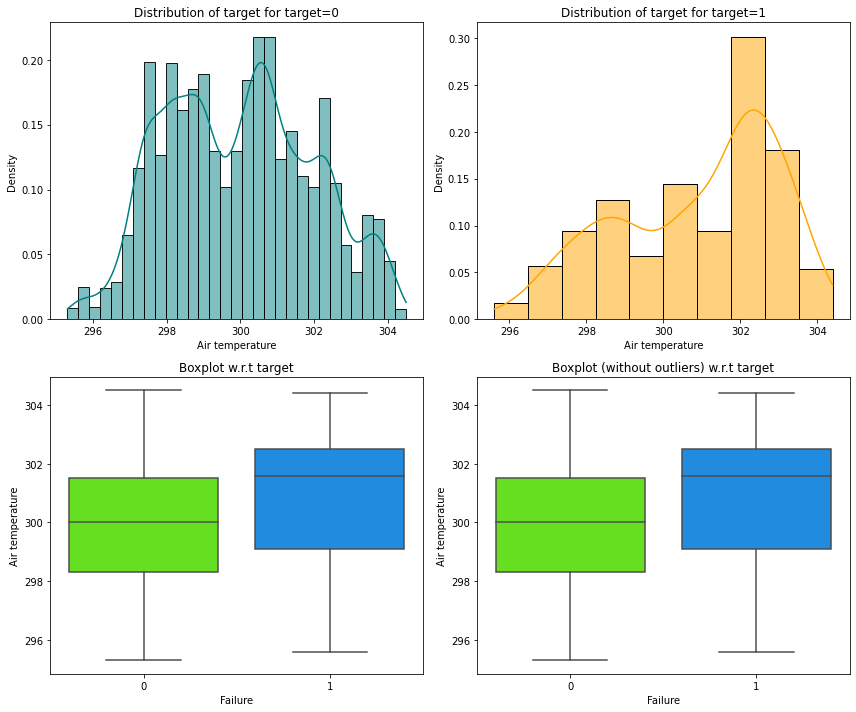

Let’s analyze the relation between Process temperature and Failure.

In [ ]:

distribution_plot_wrt_target(data, "Process temperature", "Failure")

- Most of the failures of the manufacturing system occur at higher

Process temperature.

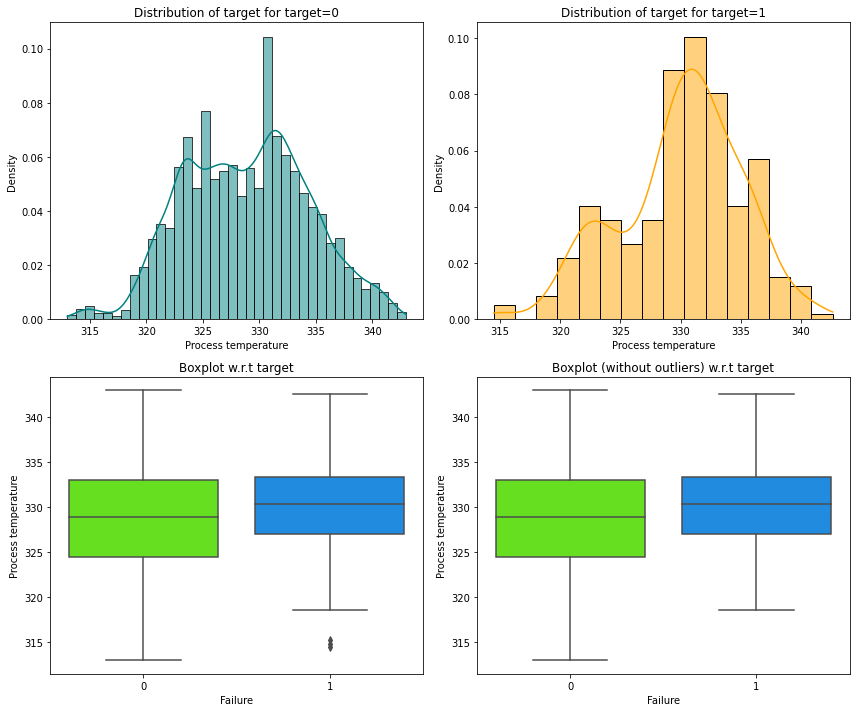

Let’s analyze the relation between Rotational speed and Failure.

In [ ]:

distribution_plot_wrt_target(data, "Rotational speed", "Failure")

- There is a clear boundary showing separation of failure status based of the values of

Rotational speed. - Manufacturing system is more prone to failure at lower

Rotational speedthan at higher rotational speed.

Data Preprocessing

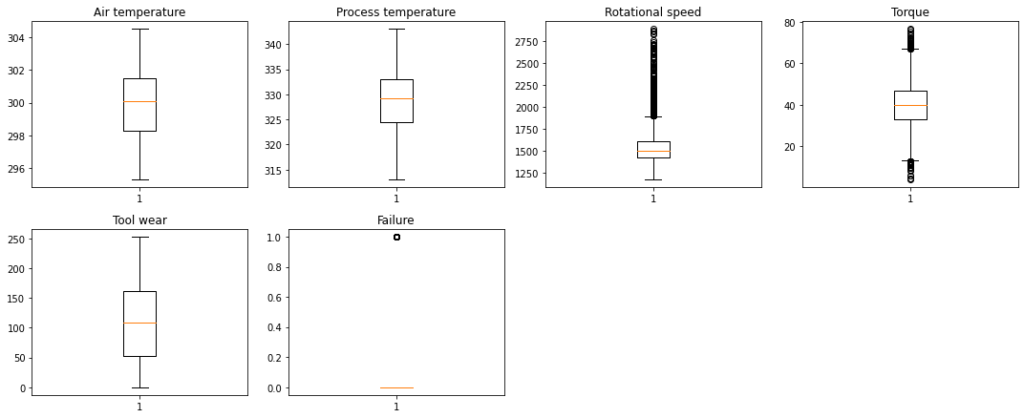

Outlier Detection

Let’s check for outliers in the data.

In [ ]:

# outlier detection using boxplot

numeric_columns = data.select_dtypes(include=np.number).columns.tolist()

plt.figure(figsize=(15, 12))

for i, variable in enumerate(numeric_columns):

plt.subplot(4, 4, i + 1)

plt.boxplot(data[variable], whis=1.5)

plt.tight_layout()

plt.title(variable)

plt.show()

Observations

- There are quite a few outliers in the data.

- However, we will not treat them as they are proper values

Data Preparation for Modeling

In [ ]:

X = data.drop(["Failure"], axis=1)

Y = data["Failure"]

X = pd.get_dummies(X, drop_first=True)

# Splitting data in train and test sets

X_train, X_test, y_train, y_test = train_test_split(

X, Y, test_size=0.30, random_state=1

)

In [ ]:

print("Shape of Training set : ", X_train.shape)

print("Shape of test set : ", X_test.shape)

print("Percentage of classes in training set:")

print(y_train.value_counts(normalize=True))

print("Percentage of classes in test set:")

print(y_test.value_counts(normalize=True))

Shape of Training set : (7000, 7) Shape of test set : (3000, 7) Percentage of classes in training set: 0 0.96629 1 0.03371 Name: Failure, dtype: float64 Percentage of classes in test set: 0 0.96567 1 0.03433 Name: Failure, dtype: float64

- We had seen that around 96.6% of observations belongs to class 0 (Not Failed) and 3.37% observations belongs to class 1 (Failed), and this is preserved in the train and test sets

Model Building

Decision Tree (default)

In [ ]:

model0 = DecisionTreeClassifier(random_state=1) model0.fit(X_train, y_train)

Out[ ]:

DecisionTreeClassifier(random_state=1)

Model Evaluation

Model evaluation criterion

Model can make wrong predictions as:

- Predicting a machine will not fail but in reality, the machine will fail (FN)

- Predicting a machine will fail but in reality, the machine will not fail (FP)

Which case is more important?

- If we predict that a machine will not fail but in reality, the machine fails, then the company will have to bear the cost of repair/replacement and also face equipment downtime losses

- If we predict that a machine will fail but in reality, the machine does not fail, then the company will have to bear the cost of inspection

- The inspection cost is generally less compared to the repair/replacement cost

How to reduce the losses?

The company would want the recall to be maximized, greater the recall score higher are the chances of minimizing the False Negatives.

In [ ]:

# defining a function to compute different metrics to check performance of a classification model built using sklearn

def model_performance_classification_sklearn(model, predictors, target):

"""

Function to compute different metrics to check classification model performance

model: classifier

predictors: independent variables

target: dependent variable

"""

# predicting using the independent variables

pred = model.predict(predictors)

acc = accuracy_score(target, pred) # to compute Accuracy

recall = recall_score(target, pred) # to compute Recall

precision = precision_score(target, pred) # to compute Precision

f1 = f1_score(target, pred) # to compute F1-score

# creating a dataframe of metrics

df_perf = pd.DataFrame(

{"Accuracy": acc, "Recall": recall, "Precision": precision, "F1": f1,},

index=[0],

)

return df_perf

In [ ]:

def confusion_matrix_sklearn(model, predictors, target):

"""

To plot the confusion_matrix with percentages

model: classifier

predictors: independent variables

target: dependent variable

"""

y_pred = model.predict(predictors)

cm = confusion_matrix(target, y_pred)

labels = np.asarray(

[

["{0:0.0f}".format(item) + "\n{0:.2%}".format(item / cm.flatten().sum())]

for item in cm.flatten()

]

).reshape(2, 2)

plt.figure(figsize=(6, 4))

sns.heatmap(cm, annot=labels, fmt="")

plt.ylabel("True label")

plt.xlabel("Predicted label")

In [ ]:

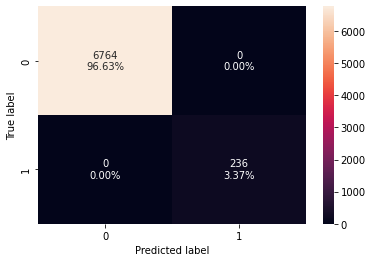

confusion_matrix_sklearn(model0, X_train, y_train)

In [ ]:

decision_tree_perf_train_without = model_performance_classification_sklearn(

model0, X_train, y_train

)

decision_tree_perf_train_without

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 1.00000 | 1.00000 | 1.00000 | 1.00000 |

In [ ]:

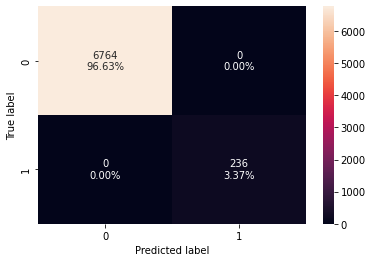

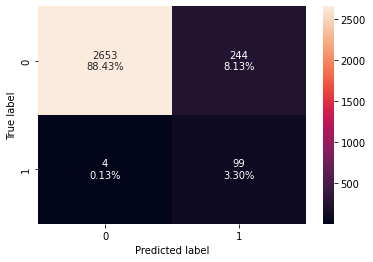

confusion_matrix_sklearn(model0, X_test, y_test)

In [ ]:

decision_tree_perf_test_without = model_performance_classification_sklearn(

model0, X_test, y_test

)

decision_tree_perf_test_without

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 0.97567 | 0.72816 | 0.62500 | 0.67265 |

Decision Tree (with class_weights)

- If the frequency of class A is 10% and the frequency of class B is 90%, then class B will become the dominant class and the decision tree will become biased toward the dominant classes

- In this case, we will set class_weight = “balanced”, which will automatically adjust the weights to be inversely proportional to the class frequencies in the input data

- class_weight is a hyperparameter for the decision tree classifier

In [ ]:

model = DecisionTreeClassifier(random_state=1, class_weight="balanced") model.fit(X_train, y_train)

Out[ ]:

DecisionTreeClassifier(class_weight='balanced', random_state=1)

In [ ]:

confusion_matrix_sklearn(model, X_train, y_train)

In [ ]:

decision_tree_perf_train = model_performance_classification_sklearn(

model, X_train, y_train

)

decision_tree_perf_train

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 1.00000 | 1.00000 | 1.00000 | 1.00000 |

- Model is able to perfectly classify all the data points on the training set.

- 0 errors on the training set, each sample has been classified correctly.

- As we know a decision tree will continue to grow and classify each data point correctly if no restrictions are applied as the trees will learn all the patterns in the training set.

- This generally leads to overfitting of the model as Decision Tree will perform well on the training set but will fail to replicate the performance on the test set.

In [ ]:

confusion_matrix_sklearn(model, X_test, y_test)

In [ ]:

decision_tree_perf_test = model_performance_classification_sklearn(

model, X_test, y_test

)

decision_tree_perf_test

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 0.97700 | 0.61165 | 0.68478 | 0.64615 |

- There is a huge disparity in performance of model on training set and test set, which suggests that the model is overfiiting.

Let’s use pruning techniques to try and reduce overfitting.

Decision Tree (Pre-pruning)

Using GridSearch for Hyperparameter tuning of our tree model

- Hyperparameter tuning is also tricky in the sense that there is no direct way to calculate how a change in the hyperparameter value will reduce the loss of your model, so we usually resort to experimentation. i.e we’ll use Grid search

- Grid search is a tuning technique that attempts to compute the optimum values of hyperparameters.

- It is an exhaustive search that is performed on a the specific parameter values of a model.

- The parameters of the estimator/model used to apply these methods are optimized by cross-validated grid-search over a parameter grid.

In [ ]:

# Choose the type of classifier.

estimator = DecisionTreeClassifier(random_state=1)

# Grid of parameters to choose from

parameters = {

"class_weight": [None, "balanced"],

"max_depth": np.arange(2, 7, 2),

"max_leaf_nodes": [50, 75, 150, 250],

"min_samples_split": [10, 30, 50, 70],

}

# Type of scoring used to compare parameter combinations

acc_scorer = make_scorer(recall_score)

# Run the grid search

grid_obj = GridSearchCV(estimator, parameters, scoring=acc_scorer, cv=5)

grid_obj = grid_obj.fit(X_train, y_train)

# Set the clf to the best combination of parameters

estimator = grid_obj.best_estimator_

# Fit the best algorithm to the data.

estimator.fit(X_train, y_train)

Out[ ]:

DecisionTreeClassifier(class_weight='balanced', max_depth=4, max_leaf_nodes=50,

min_samples_split=70, random_state=1)

In [ ]:

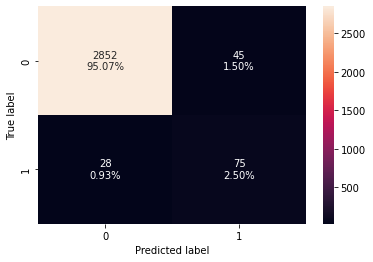

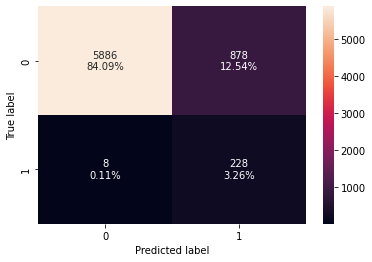

confusion_matrix_sklearn(estimator, X_train, y_train)

In [ ]:

decision_tree_tune_perf_train = model_performance_classification_sklearn(

estimator, X_train, y_train

)

decision_tree_tune_perf_train

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 0.87343 | 0.96610 | 0.20615 | 0.33979 |

In [ ]:

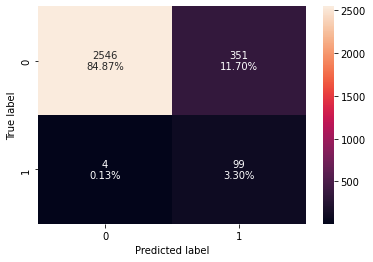

confusion_matrix_sklearn(estimator, X_test, y_test)

In [ ]:

decision_tree_tune_perf_test = model_performance_classification_sklearn(

estimator, X_test, y_test

)

decision_tree_tune_perf_test

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 0.88167 | 0.96117 | 0.22000 | 0.35805 |

- The model is giving a generalized result now since the recall scores on both the train and test data are coming to be around 0.96 which shows that the model is able to generalize well on unseen data.

In [ ]:

feature_names = list(X_train.columns) importances = estimator.feature_importances_ indices = np.argsort(importances)

In [ ]:

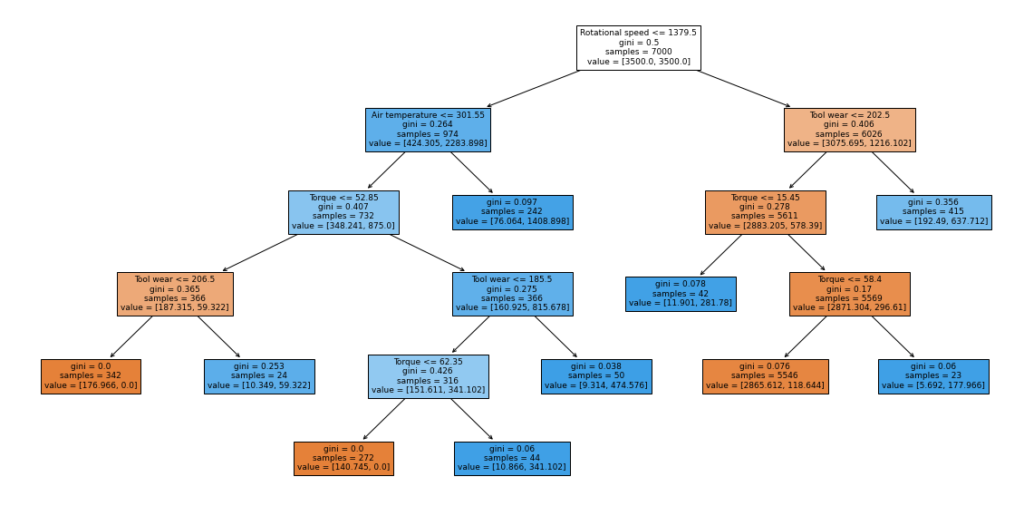

plt.figure(figsize=(20, 10))

out = tree.plot_tree(

estimator,

feature_names=feature_names,

filled=True,

fontsize=9,

node_ids=False,

class_names=None,

)

# below code will add arrows to the decision tree split if they are missing

for o in out:

arrow = o.arrow_patch

if arrow is not None:

arrow.set_edgecolor("black")

arrow.set_linewidth(1)

plt.show()

In [ ]:

# Text report showing the rules of a decision tree - print(tree.export_text(estimator, feature_names=feature_names, show_weights=True))

|--- Rotational speed <= 1379.50 | |--- Air temperature <= 301.55 | | |--- Torque <= 52.85 | | | |--- Tool wear <= 206.50 | | | | |--- weights: [176.97, 0.00] class: 0 | | | |--- Tool wear > 206.50 | | | | |--- weights: [10.35, 59.32] class: 1 | | |--- Torque > 52.85 | | | |--- Tool wear <= 185.50 | | | | |--- weights: [151.61, 341.10] class: 1 | | | |--- Tool wear > 185.50 | | | | |--- weights: [9.31, 474.58] class: 1 | |--- Air temperature > 301.55 | | |--- Process temperature <= 336.89 | | | |--- Process temperature <= 330.96 | | | | |--- weights: [1.03, 504.24] class: 1 | | | |--- Process temperature > 330.96 | | | | |--- weights: [42.95, 845.34] class: 1 | | |--- Process temperature > 336.89 | | | |--- weights: [32.08, 59.32] class: 1 |--- Rotational speed > 1379.50 | |--- Tool wear <= 202.50 | | |--- Torque <= 15.45 | | | |--- weights: [11.90, 281.78] class: 1 | | |--- Torque > 15.45 | | | |--- Torque <= 58.40 | | | | |--- weights: [2865.61, 118.64] class: 0 | | | |--- Torque > 58.40 | | | | |--- weights: [5.69, 177.97] class: 1 | |--- Tool wear > 202.50 | | |--- Tool wear <= 219.50 | | | |--- Torque <= 51.85 | | | | |--- weights: [154.72, 311.44] class: 1 | | | |--- Torque > 51.85 | | | | |--- weights: [2.59, 59.32] class: 1 | | |--- Tool wear > 219.50 | | | |--- Air temperature <= 297.20 | | | | |--- weights: [3.10, 0.00] class: 0 | | | |--- Air temperature > 297.20 | | | | |--- weights: [32.08, 266.95] class: 1

Observations from the pre-pruned tree:

Using the above extracted decision rules we can make interpretations from the decision tree model like:

- If the rotational speed is less than or equal to 1379.50, the air temperature is less than or equal to 301.55, the torque is less than or equal to 52.85 and the tool wear is greater than 206.50, then the machine is most likey to fail

Interpretations from other decision rules can be made similarly

In [ ]:

importances = estimator.feature_importances_ importances

Out[ ]:

array([0.03002803, 0.00726903, 0.40080865, 0.32726572, 0.23462857,

0. , 0. ])

In [ ]:

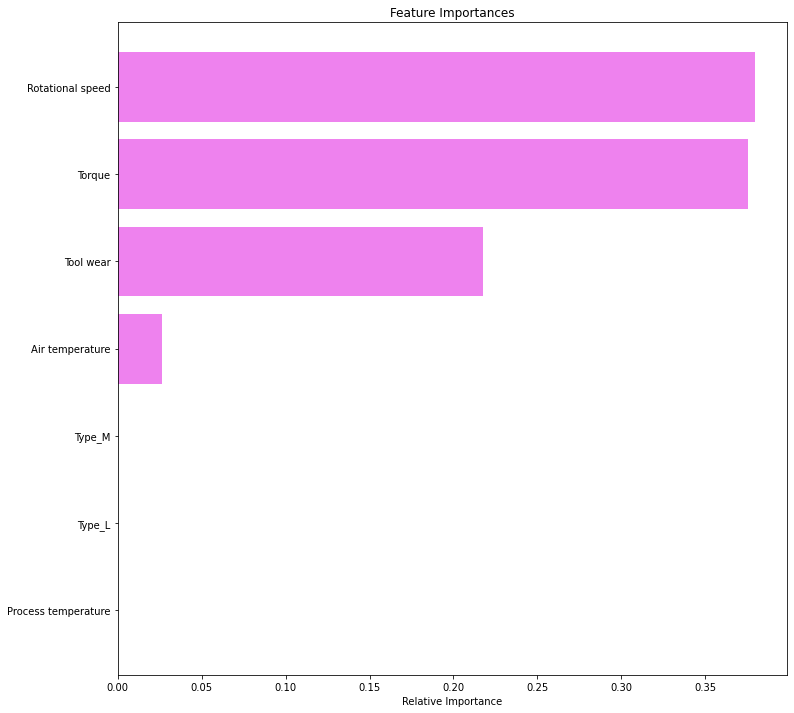

# importance of features in the tree building

importances = estimator.feature_importances_

indices = np.argsort(importances)

plt.figure(figsize=(8, 8))

plt.title("Feature Importances")

plt.barh(range(len(indices)), importances[indices], color="violet", align="center")

plt.yticks(range(len(indices)), [feature_names[i] for i in indices])

plt.xlabel("Relative Importance")

plt.show()

- In the pre tuned decision tree also, rotational speed and torque are the most important features.

Decision Tree (Post pruning)

The DecisionTreeClassifier provides parameters such as min_samples_leafand max_depth to prevent a tree from overfiting. Cost complexity pruning provides another option to control the size of a tree. In DecisionTreeClassifier, this pruning technique is parameterized by the cost complexity parameter, ccp_alpha. Greater values of ccp_alpha increase the number of nodes pruned. Here we only show the effect ofccp_alpha on regularizing the trees and how to choose a ccp_alpha based on validation scores.

Total impurity of leaves vs effective alphas of pruned tree

Minimal cost complexity pruning recursively finds the node with the “weakest link”. The weakest link is characterized by an effective alpha, where the nodes with the smallest effective alpha are pruned first. To get an idea of what values of ccp_alpha could be appropriate, scikit-learn providesDecisionTreeClassifier.cost_complexity_pruning_path that returns the effective alphas and the corresponding total leaf impurities at each step of the pruning process. As alpha increases, more of the tree is pruned, which increases the total impurity of its leaves.

In [ ]:

clf = DecisionTreeClassifier(random_state=1, class_weight="balanced") path = clf.cost_complexity_pruning_path(X_train, y_train) ccp_alphas, impurities = abs(path.ccp_alphas), path.impurities

In [ ]:

pd.DataFrame(path)

Out[ ]:

| ccp_alphas | impurities | |

|---|---|---|

| 0 | 0.00000 | -0.00000 |

| 1 | 0.00000 | -0.00000 |

| 2 | 0.00000 | -0.00000 |

| 3 | 0.00000 | -0.00000 |

| 4 | 0.00000 | -0.00000 |

| 5 | 0.00000 | -0.00000 |

| 6 | 0.00000 | -0.00000 |

| 7 | 0.00000 | -0.00000 |

| 8 | 0.00000 | -0.00000 |

| 9 | 0.00000 | -0.00000 |

| 10 | 0.00000 | 0.00000 |

| 11 | 0.00000 | 0.00000 |

| 12 | 0.00000 | 0.00000 |

| 13 | 0.00000 | 0.00000 |

| 14 | 0.00000 | 0.00000 |

| 15 | 0.00007 | 0.00015 |

| 16 | 0.00007 | 0.00029 |

| 17 | 0.00007 | 0.00044 |

| 18 | 0.00007 | 0.00058 |

| 19 | 0.00007 | 0.00073 |

| 20 | 0.00007 | 0.00088 |

| 21 | 0.00007 | 0.00117 |

| 22 | 0.00007 | 0.00132 |

| 23 | 0.00007 | 0.00147 |

| 24 | 0.00014 | 0.00175 |

| 25 | 0.00014 | 0.00231 |

| 26 | 0.00014 | 0.00246 |

| 27 | 0.00015 | 0.00260 |

| 28 | 0.00015 | 0.00304 |

| 29 | 0.00015 | 0.00319 |

| 30 | 0.00015 | 0.00333 |

| 31 | 0.00015 | 0.00348 |

| 32 | 0.00015 | 0.00363 |

| 33 | 0.00015 | 0.00377 |

| 34 | 0.00015 | 0.00392 |

| 35 | 0.00015 | 0.00407 |

| 36 | 0.00015 | 0.00421 |

| 37 | 0.00019 | 0.00479 |

| 38 | 0.00021 | 0.00522 |

| 39 | 0.00022 | 0.00565 |

| 40 | 0.00023 | 0.00680 |

| 41 | 0.00026 | 0.00783 |

| 42 | 0.00026 | 0.00809 |

| 43 | 0.00028 | 0.00837 |

| 44 | 0.00028 | 0.00893 |

| 45 | 0.00029 | 0.00921 |

| 46 | 0.00029 | 0.00950 |

| 47 | 0.00029 | 0.00978 |

| 48 | 0.00029 | 0.01095 |

| 49 | 0.00035 | 0.01338 |

| 50 | 0.00036 | 0.01409 |

| 51 | 0.00039 | 0.01448 |

| 52 | 0.00040 | 0.01488 |

| 53 | 0.00040 | 0.01568 |

| 54 | 0.00040 | 0.01608 |

| 55 | 0.00040 | 0.01648 |

| 56 | 0.00043 | 0.01692 |

| 57 | 0.00047 | 0.01739 |

| 58 | 0.00053 | 0.01792 |

| 59 | 0.00056 | 0.01848 |

| 60 | 0.00058 | 0.02021 |

| 61 | 0.00061 | 0.02082 |

| 62 | 0.00063 | 0.02271 |

| 63 | 0.00067 | 0.02338 |

| 64 | 0.00069 | 0.02407 |

| 65 | 0.00072 | 0.02551 |

| 66 | 0.00073 | 0.02625 |

| 67 | 0.00074 | 0.02698 |

| 68 | 0.00086 | 0.02784 |

| 69 | 0.00089 | 0.03138 |

| 70 | 0.00104 | 0.03242 |

| 71 | 0.00106 | 0.03348 |

| 72 | 0.00107 | 0.03455 |

| 73 | 0.00115 | 0.03570 |

| 74 | 0.00116 | 0.03919 |

| 75 | 0.00119 | 0.04632 |

| 76 | 0.00122 | 0.04754 |

| 77 | 0.00122 | 0.04875 |

| 78 | 0.00134 | 0.05543 |

| 79 | 0.00134 | 0.05812 |

| 80 | 0.00141 | 0.05953 |

| 81 | 0.00153 | 0.06106 |

| 82 | 0.00161 | 0.07559 |

| 83 | 0.00167 | 0.08559 |

| 84 | 0.00181 | 0.08740 |

| 85 | 0.00185 | 0.09109 |

| 86 | 0.00217 | 0.09544 |

| 87 | 0.00247 | 0.10037 |

| 88 | 0.00401 | 0.10839 |

| 89 | 0.01035 | 0.11875 |

| 90 | 0.01578 | 0.18187 |

| 91 | 0.04268 | 0.22456 |

| 92 | 0.05757 | 0.28212 |

| 93 | 0.06912 | 0.35124 |

| 94 | 0.14876 | 0.50000 |

In [ ]:

fig, ax = plt.subplots(figsize=(10, 5))

ax.plot(ccp_alphas[:-1], impurities[:-1], marker="o", drawstyle="steps-post")

ax.set_xlabel("effective alpha")

ax.set_ylabel("total impurity of leaves")

ax.set_title("Total Impurity vs effective alpha for training set")

plt.show()

Next, we train a decision tree using the effective alphas. The last value in ccp_alphas is the alpha value that prunes the whole tree, leaving the tree, clfs[-1], with one node.

In [ ]:

clfs = []

for ccp_alpha in ccp_alphas:

clf = DecisionTreeClassifier(

random_state=1, ccp_alpha=ccp_alpha, class_weight="balanced"

)

clf.fit(X_train, y_train)

clfs.append(clf)

print(

"Number of nodes in the last tree is: {} with ccp_alpha: {}".format(

clfs[-1].tree_.node_count, ccp_alphas[-1]

)

)

Number of nodes in the last tree is: 1 with ccp_alpha: 0.14875976077076158

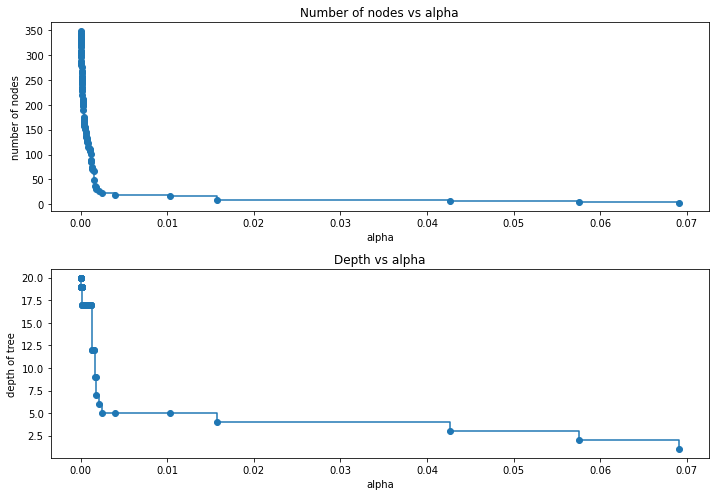

For the remainder, we remove the last element in clfs and ccp_alphas, because it is the trivial tree with only one node. Here we show that the number of nodes and tree depth decreases as alpha increases.

In [ ]:

clfs = clfs[:-1]

ccp_alphas = ccp_alphas[:-1]

node_counts = [clf.tree_.node_count for clf in clfs]

depth = [clf.tree_.max_depth for clf in clfs]

fig, ax = plt.subplots(2, 1, figsize=(10, 7))

ax[0].plot(ccp_alphas, node_counts, marker="o", drawstyle="steps-post")

ax[0].set_xlabel("alpha")

ax[0].set_ylabel("number of nodes")

ax[0].set_title("Number of nodes vs alpha")

ax[1].plot(ccp_alphas, depth, marker="o", drawstyle="steps-post")

ax[1].set_xlabel("alpha")

ax[1].set_ylabel("depth of tree")

ax[1].set_title("Depth vs alpha")

fig.tight_layout()

In [ ]:

recall_train = []

for clf in clfs:

pred_train = clf.predict(X_train)

values_train = recall_score(y_train, pred_train)

recall_train.append(values_train)

In [ ]:

recall_test = []

for clf in clfs:

pred_test = clf.predict(X_test)

values_test = recall_score(y_test, pred_test)

recall_test.append(values_test)

In [ ]:

train_scores = [clf.score(X_train, y_train) for clf in clfs] test_scores = [clf.score(X_test, y_test) for clf in clfs]

In [ ]:

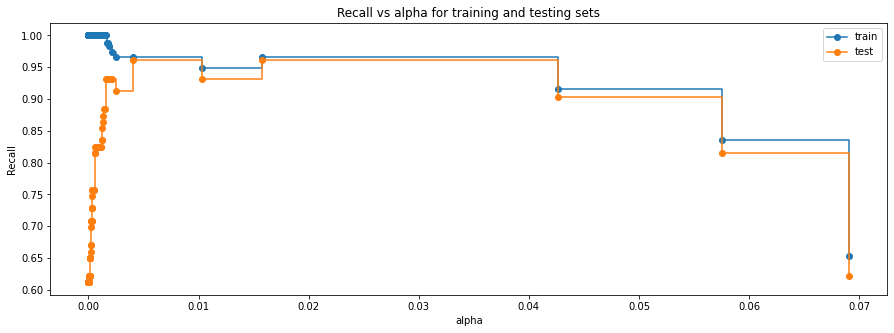

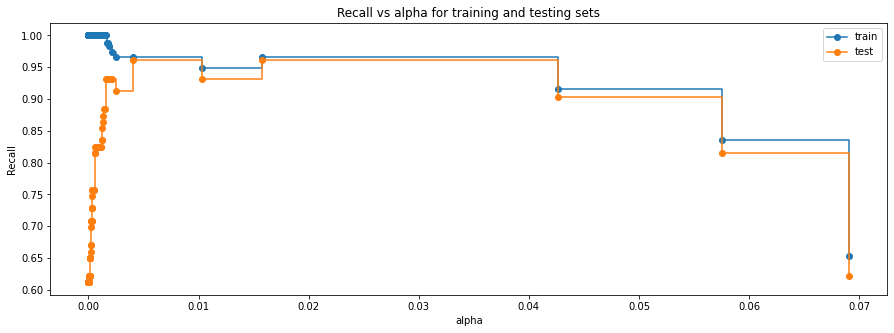

fig, ax = plt.subplots(figsize=(15, 5))

ax.set_xlabel("alpha")

ax.set_ylabel("Recall")

ax.set_title("Recall vs alpha for training and testing sets")

ax.plot(

ccp_alphas, recall_train, marker="o", label="train", drawstyle="steps-post",

)

ax.plot(ccp_alphas, recall_test, marker="o", label="test", drawstyle="steps-post")

ax.legend()

plt.show()

In [ ]:

# creating the model where we get highest train and test recall index_best_model = np.argmax(recall_test) best_model = clfs[index_best_model] print(best_model)

DecisionTreeClassifier(ccp_alpha=0.004008680486241742, class_weight='balanced',

random_state=1)

In [ ]:

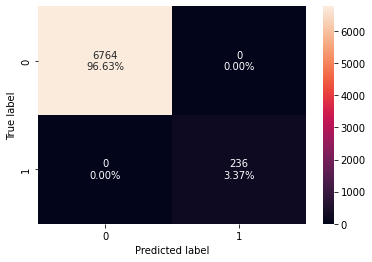

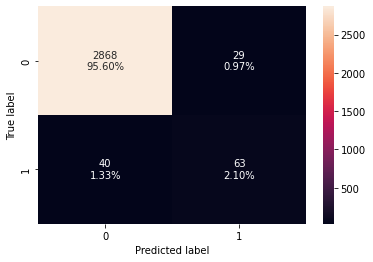

confusion_matrix_sklearn(best_model, X_train, y_train)

In [ ]:

decision_tree_post_perf_train = model_performance_classification_sklearn(

best_model, X_train, y_train

)

decision_tree_post_perf_train

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 0.91143 | 0.96610 | 0.27143 | 0.42379 |

In [ ]:

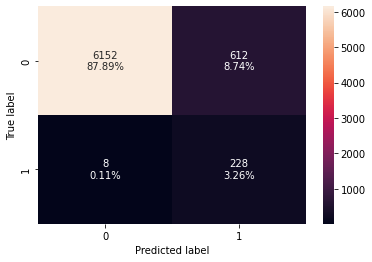

confusion_matrix_sklearn(best_model, X_test, y_test)

In [ ]:

decision_tree_post_test = model_performance_classification_sklearn(

best_model, X_test, y_test

)

decision_tree_post_test

Out[ ]:

| Accuracy | Recall | Precision | F1 | |

|---|---|---|---|---|

| 0 | 0.91733 | 0.96117 | 0.28863 | 0.44395 |

- In the post-pruned tree also, the model is giving a generalized result since the recall scores on both the train and test data are coming to be around 0.96 which shows that the model is able to generalize well on unseen data.

In [ ]:

plt.figure(figsize=(20, 10))

out = tree.plot_tree(

best_model,

feature_names=feature_names,

filled=True,

fontsize=9,

node_ids=False,

class_names=None,

)

for o in out:

arrow = o.arrow_patch

if arrow is not None:

arrow.set_edgecolor("black")

arrow.set_linewidth(1)

plt.show()

In [ ]:

# Text report showing the rules of a decision tree - print(tree.export_text(best_model, feature_names=feature_names, show_weights=True))

|--- Rotational speed <= 1379.50 | |--- Air temperature <= 301.55 | | |--- Torque <= 52.85 | | | |--- Tool wear <= 206.50 | | | | |--- weights: [176.97, 0.00] class: 0 | | | |--- Tool wear > 206.50 | | | | |--- weights: [10.35, 59.32] class: 1 | | |--- Torque > 52.85 | | | |--- Tool wear <= 185.50 | | | | |--- Torque <= 62.35 | | | | | |--- weights: [140.75, 0.00] class: 0 | | | | |--- Torque > 62.35 | | | | | |--- weights: [10.87, 341.10] class: 1 | | | |--- Tool wear > 185.50 | | | | |--- weights: [9.31, 474.58] class: 1 | |--- Air temperature > 301.55 | | |--- weights: [76.06, 1408.90] class: 1 |--- Rotational speed > 1379.50 | |--- Tool wear <= 202.50 | | |--- Torque <= 15.45 | | | |--- weights: [11.90, 281.78] class: 1 | | |--- Torque > 15.45 | | | |--- Torque <= 58.40 | | | | |--- weights: [2865.61, 118.64] class: 0 | | | |--- Torque > 58.40 | | | | |--- weights: [5.69, 177.97] class: 1 | |--- Tool wear > 202.50 | | |--- weights: [192.49, 637.71] class: 1

- We can see that the observation we got from the pre-pruned tree is also matching with the decision tree rules of the post pruned tree.

In [ ]:

importances = best_model.feature_importances_ indices = np.argsort(importances)

In [ ]:

plt.figure(figsize=(12, 12))

plt.title("Feature Importances")

plt.barh(range(len(indices)), importances[indices], color="violet", align="center")

plt.yticks(range(len(indices)), [feature_names[i] for i in indices])

plt.xlabel("Relative Importance")

plt.show()

- Rotational speed and Torque are the most important features for the post pruned tree

Comparison of Models and Final Model Selection

In [ ]:

# training performance comparison

models_train_comp_df = pd.concat(

[

decision_tree_perf_train_without.T,

decision_tree_perf_train.T,

decision_tree_tune_perf_train.T,

decision_tree_post_perf_train.T,

],

axis=1,

)

models_train_comp_df.columns = [

"Decision Tree without class_weight",

"Decision Tree with class_weight",

"Decision Tree (Pre-Pruning)",

"Decision Tree (Post-Pruning)",

]

print("Training performance comparison:")

models_train_comp_df

Training performance comparison:

Out[ ]:

| Decision Tree without class_weight | Decision Tree with class_weight | Decision Tree (Pre-Pruning) | Decision Tree (Post-Pruning) | |

|---|---|---|---|---|

| Accuracy | 1.00000 | 1.00000 | 0.87343 | 0.91143 |

| Recall | 1.00000 | 1.00000 | 0.96610 | 0.96610 |

| Precision | 1.00000 | 1.00000 | 0.20615 | 0.27143 |

| F1 | 1.00000 | 1.00000 | 0.33979 | 0.42379 |

In [ ]:

# testing performance comparison

models_test_comp_df = pd.concat(

[

decision_tree_perf_test_without.T,

decision_tree_perf_test.T,

decision_tree_tune_perf_test.T,

decision_tree_post_test.T,

],

axis=1,

)

models_test_comp_df.columns = [

"Decision Tree without class_weight",

"Decision Tree with class_weight",

"Decision Tree (Pre-Pruning)",

"Decision Tree (Post-Pruning)",

]

print("Test set performance comparison:")

models_test_comp_df

Test set performance comparison:

Out[ ]:

| Decision Tree without class_weight | Decision Tree with class_weight | Decision Tree (Pre-Pruning) | Decision Tree (Post-Pruning) | |

|---|---|---|---|---|

| Accuracy | 0.97567 | 0.97700 | 0.88167 | 0.91733 |

| Recall | 0.72816 | 0.61165 | 0.96117 | 0.96117 |

| Precision | 0.62500 | 0.68478 | 0.22000 | 0.28863 |

| F1 | 0.67265 | 0.64615 | 0.35805 | 0.44395 |

- Decision tree models with pre-pruning and post-pruning both are giving equally high recall scores on both training and test sets.

- However, we will choose the post pruned tree as the best model since it is giving a slightly high precision score on the train and test sets than the pre-pruned tree.

Conclusions and Recommendations

- The model built can be used to predict if a machine is going to fail or not and can correctly identify 96.1% of the machine failures

- Rotational speed, torque and tool wear are the most important variables in predicting whether a machine will fail or not

- From the decision tree, it has been observed that if the rotational speed is less than or equal to 1379.50, the air temperature is less than or equal to 301.55, the torque is less than or equal to 52.85 and the tool wear is greater than 206.50, then the machine is most likey to fail

- The company should give a vigilant eye for these values in order to detect machine failure.

- The company should use more data for the analysis to get more reliable results

- As the variable used vary with the type of operation (turning, drilling, etc.) being performed, the company can look to build separate models for each different type of operation

Appendix: Detailed Exploratory Data Analysis (EDA)

Univariate Analysis

Observation on Air temperature

In [ ]:

histogram_boxplot(data, "Air temperature")

- The

air temperaturedistribution looks slightly left skewed with a mean temperature around 300K. - There is no outlier present.

Observation on Process temperature

In [ ]:

histogram_boxplot(data, "Process temperature")

- The

process temperaturedistribution looks slightly left skewed with a mean temperature around 329K. - There is no outlier present.

Observation on Rotational Speed

In [ ]:

histogram_boxplot(data, "Rotational speed")

- The

rotational speedis right skewed with many outliers on the upper quartile. - Some of the manufacturing operations are performed at a higher speed.

Observation on Torque

In [ ]:

histogram_boxplot(data, "Torque")

- The distribution of

torqueis normal with mean torque around 40 Nm. - Outliers are present on both sides.

Observation on Tool Wear

In [ ]:

histogram_boxplot(data, "Tool wear")

Tool wearis uniformly distributed with some of the higher values being less frequent.

Observation on Type of product

In [ ]:

labeled_barplot(data, "Type", perc=True)

- Around 60% of products are of low quality, 30% are of medium quality whereas 10% are of high quality

Observation on Failure

In [ ]:

labeled_barplot(data, "Failure", perc=True)

- In 96.6% of observations the machine does not fail while in 3.4% of observations it fails.

Bivariate Analysis

Correlation Check

In [ ]:

cols_list = data.select_dtypes(include=np.number).columns.tolist()

cols_list.remove('Failure')

plt.figure(figsize=(12, 7))

sns.heatmap(

data[cols_list].corr(), annot=True, vmin=-1, vmax=1, fmt=".2f", cmap="Spectral"

)

plt.show()

- There’s a positive correlation between the

air temperatureandprocess temperature. - There’s a negative correlation between the

rotational speedandtorque. - No other variables are correlated. We will analyze it further.

Observation on Type vs Air temperature

In [ ]:

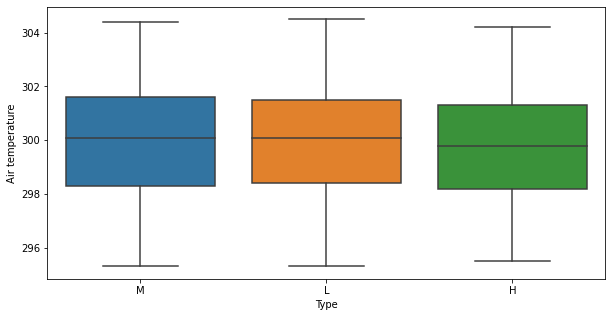

plt.figure(figsize=(10, 5)) sns.boxplot(data=data, x="Type", y="Air temperature") plt.show()

- There is no distinct difference in values of

Air temperatureandType

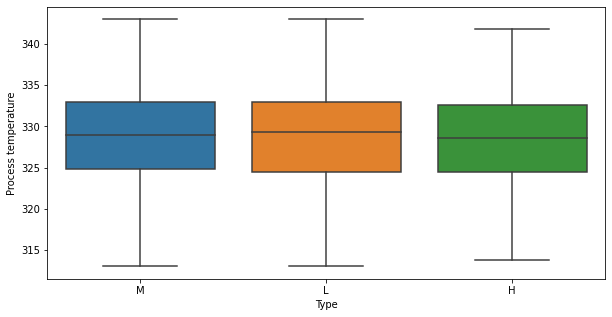

Observation on Type vs Process temperature

In [ ]:

plt.figure(figsize=(10, 5)) sns.boxplot(data=data, x="Type", y="Process temperature") plt.show()

- There is no distinct difference in values of

Process temperatureandTypefor M and L types. - Lesser

Process temperatureis observed in manufacturing H type of products.

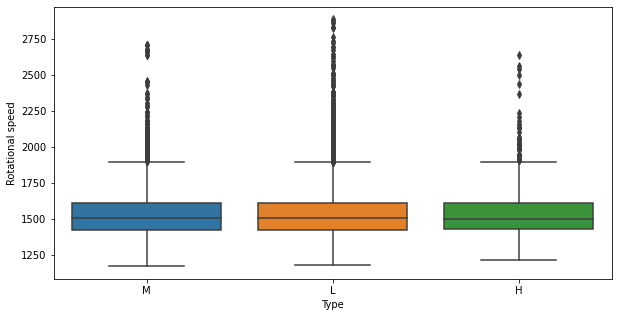

Observation on Type vs Rotational speed

In [ ]:

plt.figure(figsize=(10, 5)) sns.boxplot(data=data, x="Type", y="Rotational speed") plt.show()

- Some of the L type of products are manufactured at higher rotational speed

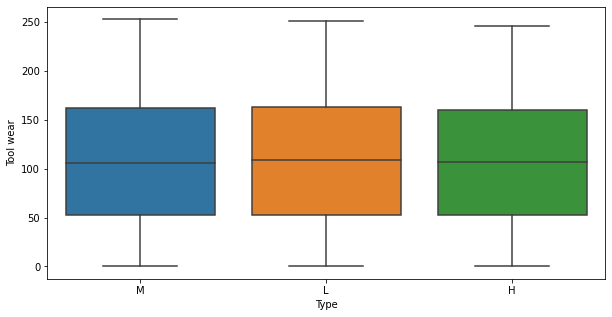

Observation on Type vs Tool wear

In [ ]:

plt.figure(figsize=(10, 5)) sns.boxplot(data=data, x="Type", y="Tool wear") plt.show()

- There is no distinct difference in values of

Tool wearandType

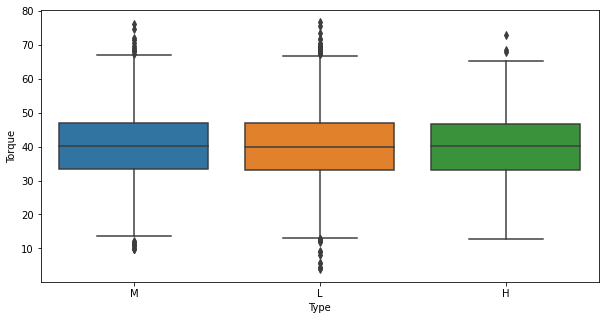

Observation on Type vs Torque

In [ ]:

plt.figure(figsize=(10, 5)) sns.boxplot(data=data, x="Type", y="Torque") plt.show()

- Some of the L type products are manufactured at lower

Toqueas compared to M and H type of products.

Failure vs Type

Let’s see how the target variable varies across the type of the product

In [ ]:

stacked_barplot(data, "Type", "Failure")

Failure 0 1 All Type All 9661 339 10000 L 5765 235 6000 M 2914 83 2997 H 982 21 1003 ------------------------------------------------------------------------------------------------------------------------

- Around 70 % of the failure occurred during machining of L type i.e., low-quality products.

- Machining of high-quality products is less prone to failure.

Distribution of numerical input variables by failure status

Let’s analyze the relation between Air temperature and Failure.

In [ ]:

distribution_plot_wrt_target(data, "Air temperature", "Failure")

- Most of the failures of the manufacturing system occur at higher

Air temperature.

Let’s analyze the relation between Process temperature and Failure.

In [ ]:

distribution_plot_wrt_target(data, "Process temperature", "Failure")

- Most of the failures of the manufacturing system occur at higher

Process temperature.

Let’s analyze the relation between Rotational speed and Failure.

In [ ]:

distribution_plot_wrt_target(data, "Rotational speed", "Failure")

- Manufacturing system is more prone to failure at lower

Rotational speedthan at higher rotational speed.

Let’s analyze the relation between Torque and Failure.

In [ ]:

distribution_plot_wrt_target(data, "Torque", "Failure")

- Most of the failures of the manufacturing system occur at higher torque as compared to lower values of torque.

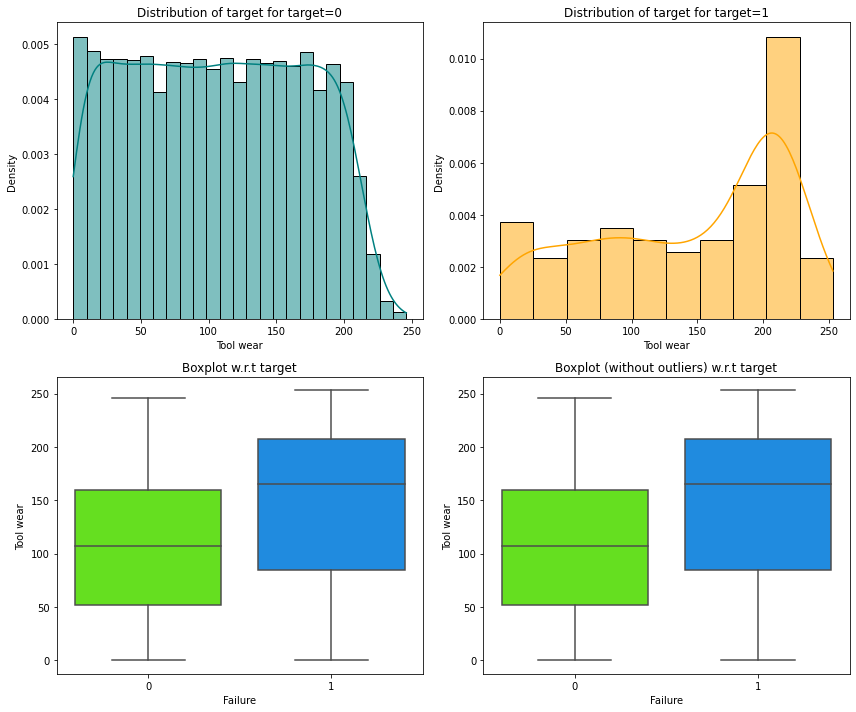

Let’s analyze the relation between Tool wear and Failure.

In [ ]:

distribution_plot_wrt_target(data, "Tool wear", "Failure")

- Most of the failures occur at higher values of tool wear than at lower tool wear.

In [ ]:

sns.pairplot(data, hue="Failure")

Out[ ]:

<seaborn.axisgrid.PairGrid at 0x7f68dcb4ac10>

- The correlation between air temperature and process temperature and torque and rotational speed is visible here too